INTRODUCTION

Product advantages:

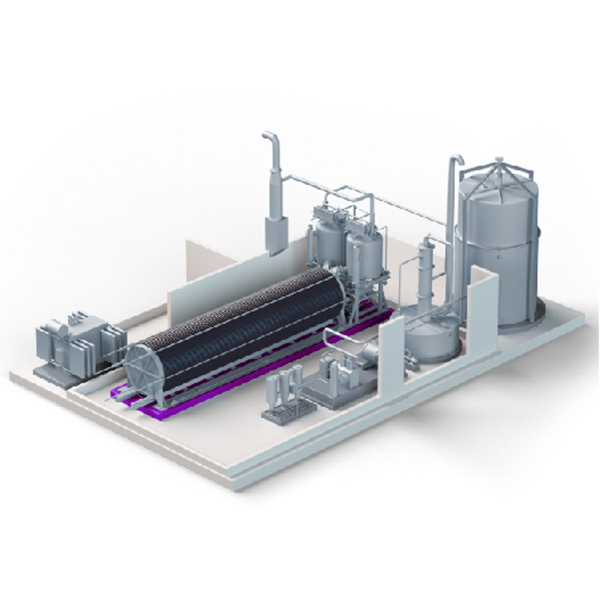

The main problems affecting the service life of hydrogen production equipment are the shedding of cathode catalyst, the degradation of anode performance, and the decline of the hydrophilic and gas-repellent performance of the diaphragm. AUYAN's hydrogen production equipment has a unique life and durability strategy.

1. Avoid Cathode Catalyst Falling Off

"Pre-spraying technology" patent, the mechanical adhesion of Raney nickel on the surface of the nickel mesh is more reliable, and the service life is better guaranteed

2. Avoid anode performance degradation

Anode edge sealing adopts a "plate electrode" design to avoid local rapid oxidation deterioration and life decay of anode

3. Avoid the degradation of the hydrophilic and air-repellent properties of the separator

While the surface layer of the diaphragm itself is hydrophilically modified, an additional hydrophilic modification layer is introduced, so that the hydrophilic and air-repellent effect is strengthened inside and outside, and the overall hydrophilic and air-repellent performance of the diaphragm is lasting and stable.

| Equipment type | Alkaline water electrolysis hydrogen production equipment |

| model | AOQING_1000A |

| Hydrogen production | 0-1000 Nm³/h |

| Oxygen production | 0-500 Nm³/h |

| Hydrogen purity | 99.999% (99.8% purity of the cell outlet) |

| DC power consumption | 3.9-4.4 kWh/Nm³ |

| Deionized water conductivity | ≤1 mS/m |

| Deionized water consumption | 900 L/h |

| Working pressure | 1.6 MPa |

| Working ambient temperature | 0-40ºC |

| Water content | ≤4 g/m3 (outlet of electrolyzer) |

| Output gas temperature | 40ºC |

| Equipment life | 30 years |

| energy conversion efficiency | > 65% |

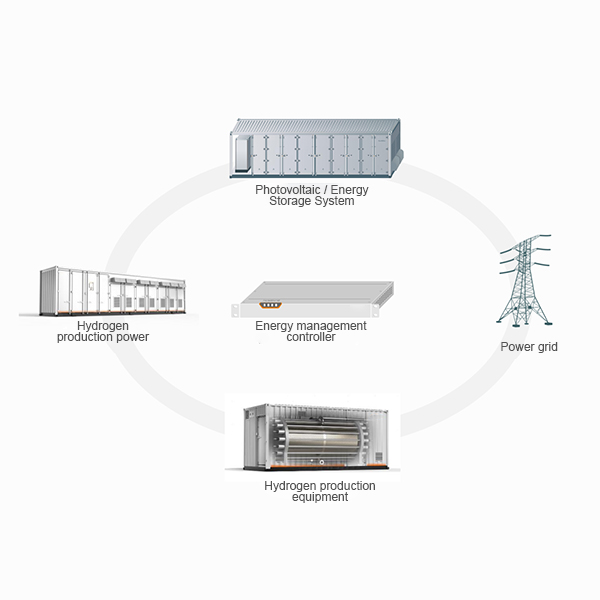

AUYAN Production Alkaline electrolysis water hydrogen production device for photovoltaic power plants, chemical plants, integrated hydrogen production and refueling stations, power plants, and laboratories.

评论

发表评论